MyTechFun.com

Filament dryers

Filament dryer comparison. There is a standard testing I repeat with each filament dryer. Results are here for comparion. The experiment is drying 2ml of water from a small sponge. The test is detailly explained in this video: https://youtu.be/6VB-pEvSed4

Results

| Name | Removed water after 30' | Removed water after 1h | Max temp | Noise (dB) | T, RH during test |

| eSun eBox* | 34.7% |

73.2% | 46°C | 34.3 | 22°C, 50% |

| eBox Lite* | 48.0% |

90.3% | 48°C | 38.7 | 22°C, 50% |

| Sunlu S1* | 18.8% |

36.3% | 42°C | 0 | 22°C, 50% |

| Sovol SH01 | 22.3% |

56.1% | 50°C | 30 | 22°C, 50% |

| Sovol SH02 | 68% |

101% | 77°C | 46.5 | 24°C, 40% |

| Creality dry box* | 39.9% |

69.9% | 51°C | 49 | 22°C, 50% |

| Creality Space Pi | 85% |

100%*** | 65°C | 42.2 | 26°C, 45% |

| Eibos Cyclopes* | 75.8% | 100%*** | 63°C | 40.8 | 22°C, 50% |

| Eibos Polyphemus* | 56% | 100%*** | 60°C | 35-36 | 24°C, 40% |

| Sunlu SP2 | 98% | 101% | 67°C | 42 | 24°C, 40% |

| Sunlu S4 | 100% | 102% | 67°C | 45 | 24°C, 45% |

| Sunlu S2 | 23% | 48.8% | 50°C | 0 | 23°C, 50%* |

| Sunlu S1 (not in group) | 15.5% | 31.1% | 40°C | 0 | 23°C, 50%* |

| Eibos Easdry | 45.2% | 91.1% | 57°C | 38.5 | 22°C, 51% |

| Eryone Snail | 32.6% | 74.5% | 55°C | 31,5 | 23°C, 52% |

| Gratkit Firefly | 67% | 100%*** | 74°C | 34 | 24°C, 40% |

| Polydryer | 92% | 102%*** | 56°C | 40.5 | 24°C, 45% |

| PrintDry Pro 3 | 88% | 100%*** | 68.5°C | 46 | 24°C, 50% |

*First 6 dryer from the list, measured next to each other, adding more heat to neigbour dryer, my mistake I noticed later. For example Sunlu S1 was measured without those neighbours too, results can be seen in the table.

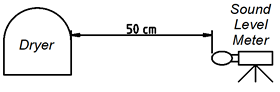

**noise measured with sound level meter located on tripod from 50cm distance, microphone directed to the box.

*** with some filament dryers the 1h measuring was over 100% (sponge had some start moisture

from environment). But in table I am entering 100%, so it is less confusing to first time viewers. Details are in the each video.

UYIGAO UA961

UYIGAO UA961

Why to use filament dryer?

Every filament absorb moisture from the air. Some of them are very sensitive to this, like PETG, Nylon, TPU etc. With these filaments usually first thing user will notice is significantly more stringing. I measured the layer adhesion too, wet PETG filament may have more stringing and 20-30% weaker layer adhesion. Sometimes, very old PLA or ABS filaments may become brittle too, but they can be saved with drying.

Drying have two main stages. First higher temperature is needed to force water molecules to the surface of the filament. In next stage we need dry environment (air around filament), so that moisture may evaporate from the material. For this some silica gel may be used or circulating of the hot (dry) air.

For some sensitive materials it is recommended to 3D print from the dryer too and after printing store the filament in some dry box or vacuum bag.

Recommended drying temperatures:

PLA 50°C, 4h

ABS 60°C 2h

PETG 65°C 2h (recommended to print from dryer)

Nylon 70°C, 12h (needs to be in dryer during 3D printing!)

PC 70°C, 6h

(recommended to print from dryer)

TPU 55°C, 4h

(recommended to print from dryer)

I can recommend the article on the Eibos website (and source for above table), where you can find more detailed information:

https://www.eibos3d.com/cyclopes-detail

All filament dryer related videos on this channel: www.mytechfun.com/videos/filament_dryer

© 2019+ mytechfun.com | Terms of Use