MyTechFun.com

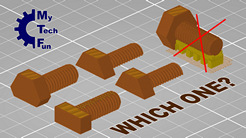

Testing horizontally 3D printed bolts without supports - how strong are these sliced screws?

Title: Testing horizontally 3D printed bolts without supports - how strong are these sliced screws?. Watch on youtube: https://youtu.be/E3WRBp-T42o

Tags: 3dprint, strength test, 3d printed bolts,

In one of my experiments I was testing horizontally and vertically 3D printed machine screws or bolts. Result was that horizontally printed bolt is much stronger, but in this case, we need to use supports and sometimes a die tool to clear the thread. Link to that video:

https://youtu.be/ZiQek0wei1g

There I got a lot of useful comments, like:

- Print the bolt in two halves and glue it or use with nut

- Cut the bolt from one side to have flat surface to start 3D printing

- Cut the screw from two sides, to have symmetrical load

In this video you can see these 3 new type of bolts but for reference I printed vertical and horizontal regular screw. M6, M8 and M10 bolts will be measured for torque, tensile and shear stress.

Contents:

0:00 introduction

2:52 design bolts in Fusion 360

5:14 slicing and 3D printing

6:45 analyzing new 3D printed bolts

10:40 tensile (pulling) test

13:10 results of tensile test

13:38 shear test

15:54 results of shear test

16:12 torque test

21:31 results of torque test

21:48 conclusions

Materials and methods:

Prusa MK3s 3D printer, Prusament PLA, 0.4mm nozzle, 0.2 and 0.15mm layer height, 215°C temperature. Printed with max wall (perimeters or shell) and 100% infill.

STL for used test specimens can be downloaded below this text.

Support my work over Patreon:

https://www.patreon.com/mytechfun

Support my work over PayPal:

https://www.mytechfun.com/donation

Download files:

m10_cutten.stl 2373 kB [View»]

m10_top.stl 1810.9 kB [View»]

m10x22.stl 2759.1 kB [View»]

m10x22_1slice.stl 2834 kB [View»]

m6_half1.stl 1624 kB [View»]

m6_half2.stl 1663.7 kB [View»]

m6x20.stl 4149.2 kB [View»]

m6x20_1slice.stl 2879.5 kB [View»]

m6x20_crop.stl 2340.5 kB [View»]

m8_bottom.stl 1848.8 kB [View»]

m8_cutten.stl 2289.8 kB [View»]

m8_top.stl 1734.6 kB [View»]

m8x22.stl 4059.9 kB [View»]

m8x22_1slice.stl 2898.8 kB [View»]

© 2019+ mytechfun.com | Terms of Use