MyTechFun.com

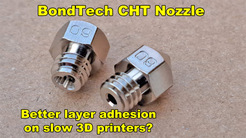

BondTech CHT nozzle - better layer adhesion on slower 3D printers? (Ender3 or Prusa MK3)

Title: BondTech CHT nozzle - better layer adhesion on slower 3D printers? (Ender3 or Prusa MK3). Watch on youtube: https://youtu.be/ZyE9A2vx5C8

Can we benefit from CHT nozzles on slower 3D printers? These nozzles are able to melt the filament much faster, very important for fast 3D printers where we need a bigger flow rate. But what about slow printers? Can we get better layer adhesion using same printing temperatures? Comparison testing of 8 nozzles, printed on Prusa MK3S and Ender-3 V2 (with MicroSwiss NG extruder).

Bontech CHT nozzles: https://www.bondtech.se/product-category/nozzles/bondtech-nozzles/bondtech-cht/

If you like my work, you could support me with a domation, but share and like are very welcome too :-)

Become a Patreon: https://www.patreon.com/mytechfun

Buy me a coffee: https://www.buymeacoffee.com/mytechfun

Mentioned in the video:

Download results in Excel table below this text.

Torque wrench: https://www.thingiverse.com/thing:4738816

@CNCKitchen CHT max flow rate research: https://www.youtube.com/watch?v=UNJdv5bFGOg

Filasin company: https://www.filasin.com/

Contents:

0:00 Introduction

3:08 Printing on Prusa MK3S

5:20 Printing on Ender3-V2

7:04 Pulling test

8:47 Results

10:14 Conclusions

#bondtech #nozzle #3dprinting

Download files:

© 2019+ mytechfun.com | Terms of Use